High-power pulsed laser with all-fiber MOPA structure

The main structural types of fiber lasers include single resonator, beam combination and master oscillating power amplifier (MOPA) structures. Among them, the MOPA structure has become one of the current research hotspots due to its ability to achieve high-performance pulsed laser output with adjustable pulse width and repetition frequency (referred to as pulse width and repetition frequency).

The working principle of the MOPA laser is as follows: The main oscillator (MO) is a high-performance seed source semiconductor laser that generates seed signal light with adjustable parameters through direct pulse modulation. The Field Programmable gate Array (FPGA) main control outputs pulse current signals with adjustable parameters, which are controlled by the drive circuit to operate the seed source and complete the initial modulation of the seed light. After receiving the control instructions from the FPGA main control board, the pump source drive circuit starts the pump source to generate pump light. After the seed light and the pump light are coupled by the beam splitter, they are respectively injected into the Yb3+ -doped double-clad optical fiber (YDDCF) in the two-stage optical amplification module. During this process, the Yb3+ ions absorb the energy of the pump light to form a population inversion distribution. Subsequently, based on the principles of traveling wave amplification and stimulated emission, the seed signal light achieves high power gain in the two-stage optical amplification module, ultimately outputting a high-power nanosecond pulsed laser. Due to the increase in peak power, the amplified pulse signal may experience pulse width compression due to the gain clamping effect. In practical applications, multi-stage amplification structures are often adopted to further enhance output power and gain efficiency.

The MOPA laser circuit system is composed of an FPGA main control board, a pump source, a seed source, a driver circuit board, an amplifier, etc. The FPGA main control board drives the seed source to output MW-level raw seed light pulses with adjustable parameters by generating pulse electrical signals with adjustable waveforms, pulse widths (5 to 200ns), and repetition rates (30 to 900kHz). This signal is input through the isolator to the two-stage optical amplification module composed of the preamplifier and the main amplifier, and finally outputs high-energy short-pulse laser through the optical isolator with collimation function. The seed source is equipped with an internal photodetector to monitor the output power in real time and feed it back to the FPGA main control board. The main control board controls the pump drive circuits 1 and 2 to achieve the opening and closing operations of pump sources 1, 2 and 3. When the photodetector fails to detect the signal light output, the main control board will shut off the pump source to prevent damage to the YDDCF and optical devices due to the lack of seed light input

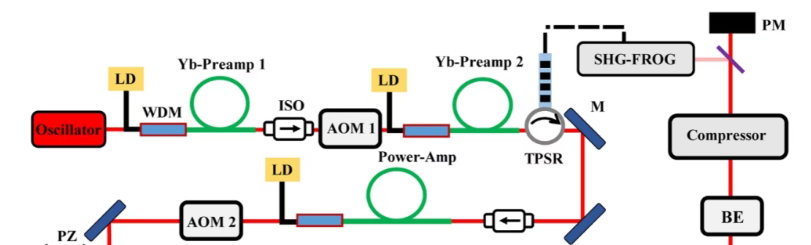

The MOPA laser optical path system adopts an all-fiber structure and consists of a main oscillation module and a two-stage amplification module. The main oscillation module takes a semiconductor laser diode (LD) with a central wavelength of 1064nm, a linewidth of 3nm, and a maximum continuous output power of 400mW as the seed source, and combines it with a fiber Bragg grating (FBG) with a reflectivity of 99%@1063.94nm and a linewidth of 3.5nm to form a wavelength selection system. The 2-stage amplification module adopts a reverse pump design, and YDDCF with core diameters of 8 and 30μm are respectively configured as gain media. The corresponding coating pump absorption coefficients are 1.0 and 2.1dB/m@915nm, respectively.

Post time: Sep-17-2025