Optical path design of polarized fiber narrow-linewidth laser

1. Overview

1018 nm polarized fiber narrow-linewidth laser. The working wavelength is 1018 nm, the laser output power is 104 W, the spectral widths of 3 dB and 20 dB are ~21 GHz and ~72 GHz respectively, the polarization extinction ratio is >17.5 dB, and the beam quality is high (2 x M – 1.62 and 2 y M) A laser system with a slope efficiency of 79% (∼1.63).

2. Optical path description

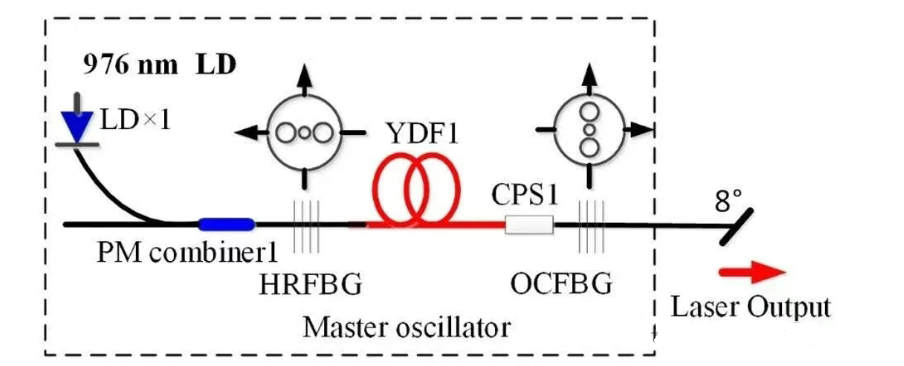

In a polarized fiber narrow-linewidth laser, the linearly polarized fiber laser oscillator is composed of a pair of polarization-maintaining fiber gratings and a 1.5-meter-long 10/125 μm ytterbium-doped double-clad polarization-maintaining fiber as the gain medium. The absorption coefficient of this optical fiber at 976 nm is 5 dB/m. The laser oscillator is pumped by a 976 nm wavelength-locked semiconductor laser with a maximum power of 27 W through a polarity-maintaining (1+1)×1 beam combiner. The high reflection grating has a reflectivity of over 99%, and the 3 dB reflection bandwidth is approximately 0.22 nm. The low reflectivity of the grating is 40%, and the 3 dB reflection bandwidth is approximately 0.216 nm. The central reflection wavelengths of both gratings are at 1018 nm. To balance the output power of the laser resonator and the ASE suppression ratio, the low reflectivity of the grating was optimized to 40%. The tail fiber of the high-reflection grating is fused to the gain fiber, while the tail fiber of the low-reflection grating is rotated 90° and fused to the tail fiber of the cladding filter. Thus, the peak position of the fast-axis reflection wavelength of the high-reflection grating matches that of the slow-axis reflection wavelength of the low-reflection grating. In this way, only one polarized laser can oscillate in the resonant cavity. The remaining pump light in the optical fiber cladding is filtered out by a self-made cladding filter fused into the resonant cavity, and the output pigtail is beveled by 8° to prevent end face feedback and parasitic oscillation.

3. Background knowledge

The generation mechanism of linearly polarized fiber lasers: Due to stress birefringence, the pear-shaped polarization-maintaining fiber has two orthogonal polarization axes, known as the fast axis and the slow axis. Generally, since the refractive index of the slow axis is greater than that of the fast axis, the grating written on the polarization-maintaining fiber has two different central wavelengths. The resonant cavity of a linearly polarized fiber laser is usually composed of two polarization-maintaining gratings. The wavelengths of the low-reflection grating and the high-reflection grating on the fast axis and the slow axis correspond respectively. When the reflection bandwidth of the polarization-maintaining grating is narrow enough, the transmission spectra in the fast axis and the slow axis directions can be separated, and both wavelengths can vibrate within the resonant cavity. According to the dual-wavelength oscillation principle of the polarization-maintaining grating, in the experiment, the parallel welding method can be adopted to achieve it. During welding, the polarization-maintaining axes of the two gratings are aligned. In this way, the two transmission peaks of the high-reflection grating correspond to those of the low-reflection grating, and thus dual-wavelength laser output can be realized.

In actual laser polarization-maintaining systems, linear skew is an important indicator for evaluating the output characteristics of linearly polarized lasers. Generally, the period of a high-reflectance grating is greater than that of a low-reflectance grating. To achieve a linearly polarized laser with a high PER value, only one polarization peak needs to vibrate. When the fast axis of the low-reflectance grating is along the slow axis of the high-reflectance grating, The central wavelength in the fast axis direction of the low-reflection grating corresponds to that in the slow axis direction of the high-reflection grating, while the transmission peak in the slow axis direction of the low-reflection grating does not correspond to the transmission peak in the fast axis direction of the high-reflection grating. In this way, one transmission peak can be vibrated. Similarly, when the slow axis of a low-reflectance grating is along the fast axis of a high-reflectance grating, the central wavelength of the slow axis of the low-reflectance grating corresponds to that of the fast axis of the high-reflectance grating, while the transmission peak of the fast axis of the low-reflectance grating does not correspond to that of the slow axis of the high-reflectance grating. In this way, one transmission peak can also be vibrated. Both of the above two methods can achieve linearly polarized laser output. According to the single-wavelength linearly polarized laser oscillation principle of the polarization-maintaining grating, in the experiment, the orthogonal splicing method can be adopted to achieve it. When the splicing Angle of the polarization-maintaining axes of the high reflection grating and the low reflection grating is 90°, the transmission peak in the slow axis direction of the high reflection grating corresponds to the transmission peak in the fast axis direction of the low reflection grating, and thus the output of single-wavelength linearly polarized fiber laser can be realized.

Post time: Sep-12-2025