The characteristics of AOM acousto-optic modulator

Withstand high optical power

The AOM acousto-optic modulator can withstand strong laser power, ensuring that high-power lasers can pass through smoothly. In an all-fiber laser link, the fiber acousto-optic modulator converts continuous light into pulsed light. Due to the relatively low duty cycle of the optical pulse, most of the light energy is located within the zero-order light. The first-order diffraction light and the zero-order light outside the acousto-optic crystal propagate in the form of divergent Gaussian beams. Although they meet the strict separability conditions, part of the light energy of the zero-order light accumulates at the edge of the optical fiber collimator and cannot be transmitted through the optical fiber, eventually burning through the optical fiber collimator. The diaphragm structure is placed in the optical path through a high-precision six-dimensional adjustment frame to restrict the transmission of diffracted light at the center of the collimator, and the zero-order light is transmitted to the housing to prevent the zero-order light from burning out the optical fiber collimator.

Rapid rise time

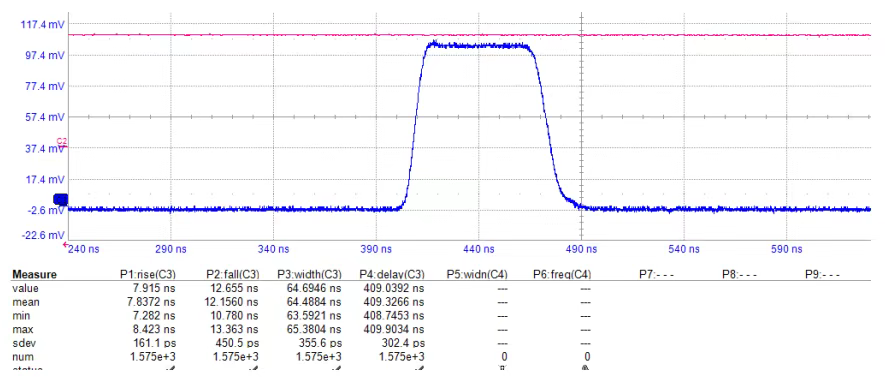

In an all-fiber laser link, the fast rise time of the optical pulse of the AOM acouste-optic modulator ensures that the system signal pulse can pass through effectively to the greatest extent, while preventing the base noise from entering the time-domain acouste-optic shutter (time-domain pulse gate). The core to achieving a rapid rise time of optical pulses lies in reducing the transit time of ultrasonic waves through the light beam. The main methods include reducing the waist diameter of the incident light beam or using materials with high sound velocity to fabricate acoust-optic crystals.

Figure1 Rise time of light pulse

Low power consumption and high reliability

Spacecraft have limited resources, harsh conditions and complex environments, which impose higher requirements on the power consumption and reliability of optical fiber AOM modulators. The optical fiber AOM modulator adopts a special tangential acousto-optic crystal, which has a high acousto-optic quality factor M2. Therefore, under the same diffraction efficiency conditions, the required driving power consumption is low. The optical fiber acoust-optic modulator adopts this low-power design, which not only reduces the demand for driving power consumption and saves the limited resources in spacecraft, but also lowers the electromagnetic radiation of the driving signal and alleviates the heat dissipation pressure on the system. According to the prohibited (restricted) process requirements of spacecraft products, the conventional crystal installation method of optical fiber acousti-optic modulators only adopts the single-sided silicone rubber bonding process. Once the silicone rubber fails, the technical parameters of the crystal will change under vibration conditions, which does not meet the process requirements of aerospace products. In the laser link, the crystal of the optical fiber acoust-optic modulator is fixed by combining mechanical fixation with silicone rubber bonding. The installation structure of the upper and lower bottom surfaces is as symmetrical as possible, and at the same time, the contact area between the crystal surface and the installation housing is maximized. It has the advantages of strong heat dissipation capacity and symmetrical temperature field distribution. Conventional collimators are fixed by bonding silicone rubber. Under conditions of high temperature and vibration, they may shift, affecting product performance. The mechanical structure is now adopted to fix the optical fiber collimator, which enhances the product stability and meets the process requirements of aerospace products.

Post time: Jul-03-2025