Using optoelectronic co-packaging technology to solve massive data transmission

Driven by the development of computing power to a higher level, the amount of data is rapidly expanding, especially the new data center business traffic such as AI large models and machine learning is promoting the growth of data from end to end and to users. Massive data needs to be transferred quickly to all angles, and the data transmission rate has also developed from 100GbE to 400GbE, or even 800GbE, to match the surging computing power and data interaction needs. As line rates have increased, the board-level complexity of related hardware has greatly increased, and traditional I/O has been unable to cope with the various demands of transmitting high-speed signals from ASics to the front panel. In this context, CPO optoelectronic co-packaging is sought after.

Data processing demand surges,CPO optoelectronic co-seal attention

In the optical communication system, the optical module and the AISC (Network switching chip) are packaged separately, and the optical module is plugged into the front panel of the switch in a pluggable mode. The pluggable mode is no stranger, and many traditional I/O connections are connected together in pluggable mode. Although pluggable is still the first choice on the technical route, the pluggable mode has exposed some problems at high data rates, and the connection length between the optical device and the circuit board, signal transmission loss, power consumption, and quality will be restricted as the data processing speed needs further increase.

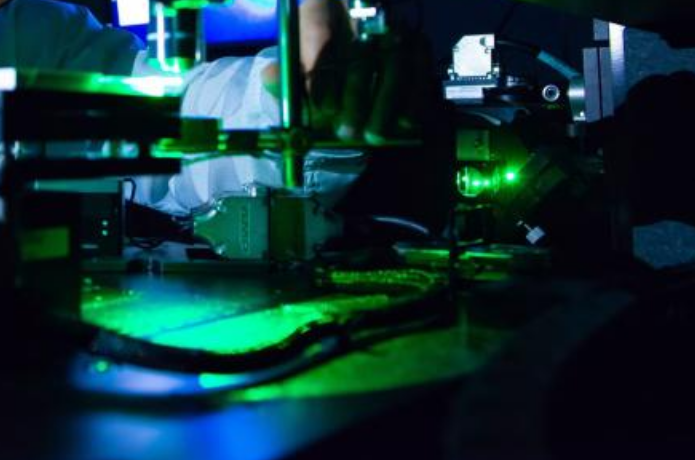

In order to solve the constraints of traditional connectivity, CPO optoelectronic co-packaging has begun to receive attention. In Co-packaged optics, optical modules and AISC (Network switching chips) are packaged together and connected through short-distance electrical connections, thus achieving compact optoelectronic integration. The advantages of size and weight brought about by CPO photoelectric co-packaging are obvious, and the miniaturization and miniaturization of high-speed optical modules are realized. The optical module and AISC (Network switching chip) are more centralized on the board, and the fiber length can be greatly reduced, which means that the loss during transmission can be reduced.

According to Ayar Labs’ test data, CPO opto-co-packaging can even directly reduce power consumption by half compared to pluggable optical modules. According to Broadcom’s calculation, on the 400G pluggable optical module, the CPO scheme can save about 50% in power consumption, and compared with the 1600G pluggable optical module, the CPO scheme can save more power consumption. The more centralized layout also makes the interconnection density greatly increased, the delay and distortion of the electrical signal will be improved, and the transmission speed restriction is no longer like the traditional pluggable mode.

Another point is the cost, today’s artificial intelligence, server and switch systems require extremely high density and speed, current demand is increasing rapidly, without the use of CPO co-packaging, the need for a large number of high-end connectors to connect the optical module, which is a great cost. CPO co-packaging can reduce the number of connectors is also a large part of reducing the BOM. CPO photoelectric co-packaging is the only way to achieve high speed, high bandwidth and low power network. This technology of packaging silicon photoelectric components and electronic components together makes the optical module as close as possible to the network switch chip to reduce channel loss and impedance discontinuity, greatly improve the interconnection density and provide technical support for higher rate data connection in the future.

Post time: Apr-01-2024