Overview of high power semiconductor laser development part one

As efficiency and power continue to improve, laser diodes(laser diodes driver) will continue to replace traditional technologies, thereby changing the way things are made and enabling the development of new things. Understanding of the significant improvements in high-power semiconductor lasers is also limited. The conversion of electrons to lasers via semiconductors was first demonstrated in 1962, and a wide variety of complementary advances have followed that have driven huge advances in the conversion of electrons to high-productivity lasers. These advances have supported important applications from optical storage to optical networking to a wide range of industrial fields.

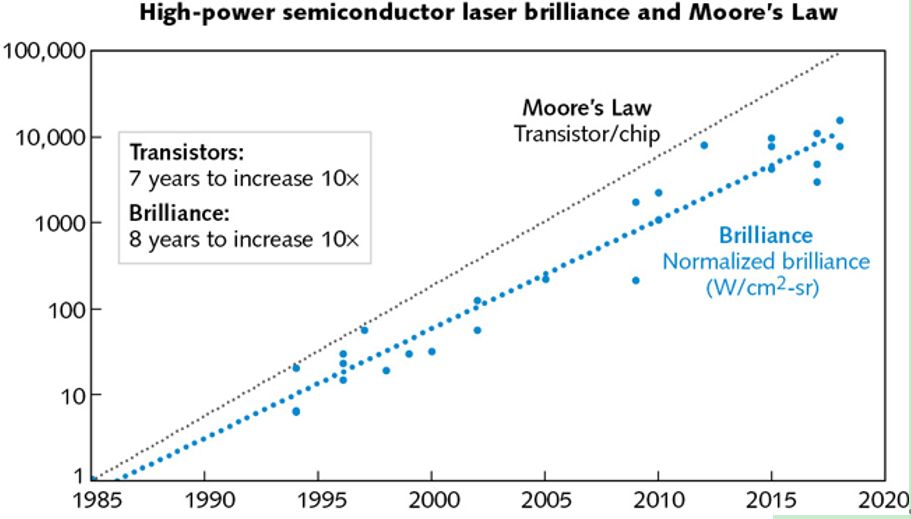

A review of these advances and their cumulative progress highlights the potential for even greater and more pervasive impact in many areas of the economy. In fact, with the continuous improvement of high-power semiconductor lasers, its application field will accelerate the expansion, and will have a profound impact on economic growth.

Figure 1: Comparison of luminance and Moore’s law of high power semiconductor lasers

Diode-pumped solid-state lasers and fiber lasers

Advances in high-power semiconductor lasers have also led to the development of downstream laser technology, where semiconductor lasers are typically used to excite (pump) doped crystals (diode-pumped solid-state lasers) or doped fibers (fiber lasers).

Although semiconductor lasers provide efficient, small, and low-cost laser energy, they also have two key limitations: they do not store energy and their brightness is limited. Basically, many applications require two useful lasers; One is used to convert electricity into a laser emission, and the other is used to enhance the brightness of that emission.

Diode-pumped solid-state lasers.

In the late 1980s, the use of semiconductor lasers to pump solid-state lasers began to gain significant commercial interest. Diode-pumped solid-state lasers (DPSSL) dramatically reduce the size and complexity of thermal management systems (primarily cycle coolers) and gain modules, which historically have used arc lamps to pump solid-state laser crystals.

The wavelength of the semiconductor laser is selected based on the overlap of spectral absorption characteristics with the gain medium of the solid-state laser, which can significantly reduce the thermal load compared to the wideband emission spectrum of the arc lamp. Considering the popularity of neodymium-doped lasers emitting 1064nm wavelength, the 808nm semiconductor laser has become the most productive product in semiconductor laser production for more than 20 years.

The improved diode pumping efficiency of the second generation was made possible by the increased brightness of multi-mode semiconductor lasers and the ability to stabilize narrow emission linewidths using bulk Bragg gratings (VBGS) in the mid-2000s. The weak and narrow spectral absorption characteristics of around 880nm have aroused great interest in spectrally stable high brightness pump diodes. These higher performance lasers make it possible to pump neodymium directly at the upper laser level of 4F3/2, reducing quantum deficits and thereby improving fundamental mode extraction at higher average power, which would otherwise be limited by thermal lenses.

By the early second decade of this century, we were witnessing a significant power increase in single-transverse mode 1064nm lasers, as well as their frequency conversion lasers operating in the visible and ultraviolet wavelengths. Given the long upper energy lifetime of Nd: YAG and Nd: YVO4, these DPSSL Q-switched operations provide high pulse energy and peak power, making them ideal for ablative material processing and high-precision micromachining applications.

Post time: Nov-06-2023